Elron company carries out the production of various devices and devices, both according to the drawings and 3D models of the Customer, and according to the independently developed design documentation at the request of the Customer.

This includes the following categories:

- Devices for medicine (wearable devices, mobile (movable) devices, stationary devices);

- Devices for everyday use (wearable devices, movable and stationary);

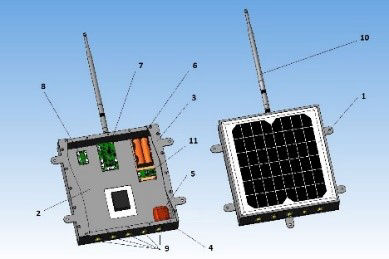

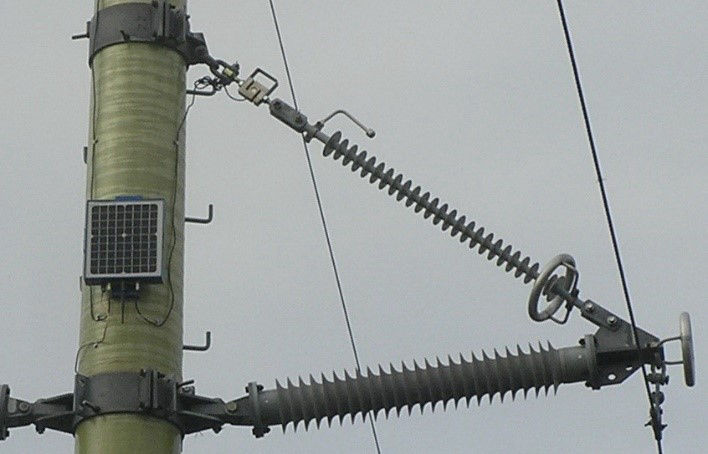

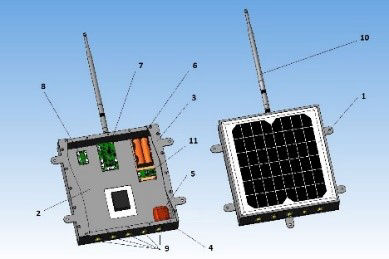

- Instruments for the electric power industry for various purposes, including testing devices and complex electric power equipment;

- Other devices for other industries.

The devices produced can be used various kinds of membranes (including different IP protection levels as well as the execution devices for protection from the external environment):

- metal;

- plastic;

- silicone;

- polyurethane;

- other required structural materials (epoxy composition, composite materials, etc.).

Depending on the needs of the volumes produced device together with Customers to develop production technology, including the production of formulations developed products often use different technologies, depending on the stage of readiness of the device:

- in the early stages (mockups, prototypes, small-scale products) - with insignificant production volumes and collection of feedback from end users - the use of technologies that allow you to quickly obtain a product without significant capital investments (as a rule, the reverse side of the coin is a higher cost of manufacturing a product). Examples: making the body of a product out of polyurethane instead of plastic injection molding, or using free-molding silicones instead of pressing or injection molding silicones.

- at more mature stages (small-scale products, serial products) - the use of technologies that require capital investments and require additional start-up time (production of molds for plastic injection under pressure, molds for pressing or injection molding of silicone, etc.), but having indisputable advantages - low cost of manufacturing a product and high productivity.

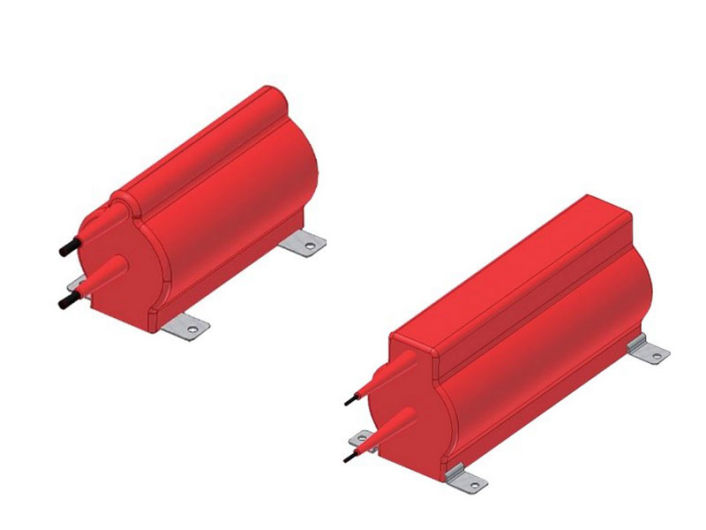

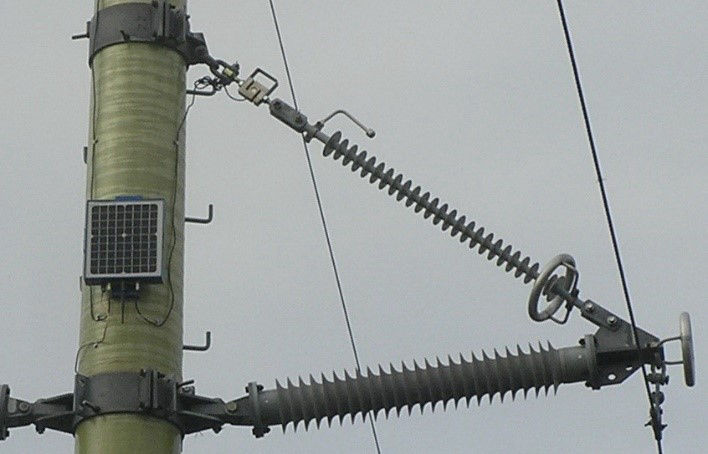

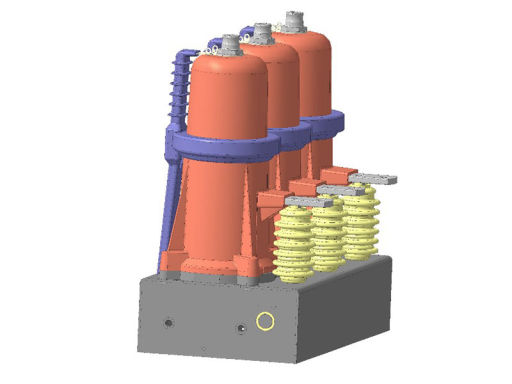

In some cases, the manufacturing technology is determined by the characteristics of the product application, and cannot be changed without deteriorating the product's characteristics. For example, in the photo below there are damping RC-circuits for the protection of transformers and electric motors of 0.66, 6, 10 kV, the design of the product is determined by the need to organize high dielectric strength in the volume of the product between its elements: